为什么研究电动汽车电池从未如此安全?

电池测试设备的进步使电池测试的过程更加安全。随着更多 精密和准确的测试设备。因此,电池中最微小的变化都能在成为关键问题之前被检测出来。改进后的设备还可以提供一个更稳定和可控的测试环境,使得 研究和开发过程 更为有效。

电动汽车电池的安全问题

While electric vehicles (EV) have been on the road for a while, questions regarding the battery’s stability and safety still come up. A few of the major, key issues with EV batteries are flammability, gases, and trauma to the battery cell.

As with any device that uses lithium-ion batteries, flammability is a huge concern with EV batteries. There have been cases where EVs have experienced thermal runaway events with catastrophic failures. Battery fires require special equipment to extinguish, and if one’s not careful, the batteries can reignite even after the fire is put out.

在电池中发现的常见电解质是碳酸盐和一种溶解盐的混合物。在热失控的情况下,分解的电解质会导致电池内形成气体,增加电池内的压力,导致有毒气体的释放。

对电池组的创伤和冲击也会大大影响其能力,并损害其稳定性和安全性。据报道,电动车在发生事故后几天就会自燃,这表明如果电池没有得到适当的监测,风险是真实存在的。 在测试过程中也是如此;即使在实验室环境中也是如此。

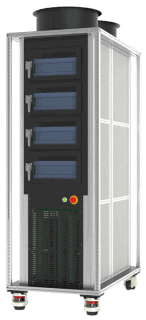

How Arbin’s equipment is designed to test EV batteries

Arbin’s equipment allows batteries to be tested using dynamic cycling. Traditional batteries are mainly tested with constant current charge/discharge profiles. On the other hand, EV batteries need to charge and discharge dynamically, based on the car’s action.

Arbin’s systems make putting the battery through a dynamic cycle easy. Using Arbin’s software, standardized test profiles, such as USACB’s FUDS profile can be easily uploaded into the testing system, allowing batteries to be safely and efficiently tested according to regional, national, and international standards just by uploading a text file of time-vs-power or time-vs-current data to simulate the drive cycle. High quality and precise testing equipment detect the slightest change in the battery, allowing researchers to detect any issues early on in the testing process and know better what materials and situations affect battery health and life. Researchers can catch these changes and make appropriate adjustments to the battery before it becomes a critical issue. It also allows manufacturers to create comprehensive safety guidelines for use of the battery. Battery test equipment from other manufacturers has been shown to significantly average the output of a dynamic drive profile and fails to accurately reproduce the real-world requirements.

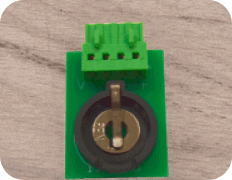

It is also possible to have the EV battery pack’s battery management system (BMS) fully control the Arbin tester charge/discharge via CANBus协议.这个软件并不像其他品牌的测试设备那样局限于截止限制或安全条件,还可以作为动态控制值。

温度稳定性也是测试电动车电池的关键。如前所述,电池过热是一个严重的安全隐患。创造一个稳定的热环境来测试电池是安全测试的关键。在发生热失控或串联故障时,也必须控制任何问题,以免影响测试室中的其他电池。

Arbin’s multi-chamber equipment 在测试过程中隔离每个电池单元或电池对,创造一个更安全和封闭的测试环境,保持温度稳定。每个试验室都是热隔离的,可以有自己独特的温度设定点,以防止电池在测试期间相互影响。这是一种更安全、更准确的测试方法,可以看到温度对电池的影响。

总结

电池是全球日益增长的能源储存需求的关键组成部分,包括电动汽车。因此,测试过程必须能够满足技术发展所需的研究要求。更好的测试设备不仅加速了测试过程,使制造商能够以更快的速度进行创新和改进,而且还使测试和电池的创造在整体上更加安全。