Why researching Electric Vehicles batteries has never been safer

Advancement in battery testing equipment has made the process of battery testing safer. With more precise and accurate testing equipment], the smallest changes in a battery can be detected before it becomes a critical issue. Improved equipment also allows for a more stable and controlled testing environment, making the research and development process much more efficient.

The safety concerns with EV batteries

While electric vehicles (EV) have been on the road for a while, questions regarding the battery’s stability and safety still come up. A few of the major, key issues with EV batteries are flammability, gases, and trauma to the battery cell.

As with any device that uses lithium-ion batteries, flammability is a huge concern with EV batteries. There have been cases where EVs have experienced thermal runaway events with catastrophic failures. Battery fires require special equipment to extinguish, and if one’s not careful, the batteries can reignite even after the fire is put out.

Common electrolytes found in batteries are mixtures of carbonates and a dissolved salt. In the event of a thermal runaway, decomposing electrolytes lead to a formation of gases within the cell, increasing pressure within the battery, leading to the release of toxic gas.

Trauma and impact to the battery pack can also greatly affect its capabilities and compromise its stability and safety. EVs have been reported to spontaneously combust days after being in an accident, showing how the risks are real if batteries are not properly monitored. This is equally true during testing; even in a lab environment.

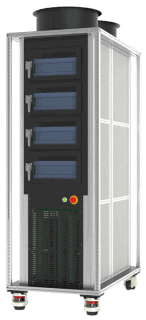

How Arbin’s equipment is designed to test EV batteries

Arbin’s equipment allows batteries to be tested using dynamic cycling. Traditional batteries are mainly tested with constant current charge/discharge profiles. On the other hand, EV batteries need to charge and discharge dynamically, based on the car’s action.

Arbin’s systems make putting the battery through a dynamic cycle easy. Using Arbin’s software, standardized test profiles, such as USACB’s FUDS profile can be easily uploaded into the testing system, allowing batteries to be safely and efficiently tested according to regional, national, and international standards just by uploading a text file of time-vs-power or time-vs-current data to simulate the drive cycle. High quality and precise testing equipment detect the slightest change in the battery, allowing researchers to detect any issues early on in the testing process and know better what materials and situations affect battery health and life. Researchers can catch these changes and make appropriate adjustments to the battery before it becomes a critical issue. It also allows manufacturers to create comprehensive safety guidelines for use of the battery. Battery test equipment from other manufacturers has been shown to significantly average the output of a dynamic drive profile and fails to accurately reproduce the real-world requirements.

It is also possible to have the EV battery pack’s battery management system (BMS) fully control the Arbin tester charge/discharge via CANBus protocol. This software is not limited to cutoff limits or safety conditions like other brands of test equipment, but can also be used as dynamic control values.

Temperature stability is also key in testing EV batteries. As mentioned before, overheating batteries is a serious safety hazard. Creating a stable thermal environment in which batteries can be tested is crucial to safe testing. It is also imperative to contain any problems in the event of a thermal runaway or cascade failure so as not to affect other batteries within the test chamber.

Arbin’s multi-chamber equipment isolates each battery cell or pairs of cells during testing, creating a safer and contained test environment that maintains temperature stability. Each chamber is thermally isolated and can have its own unique temperature set point so as to keep batteries from affecting each other during testing. This is a safer and more accurate testing method to see how temperature affects batteries.

Conclusion

Batteries are a critical component of the increasing global need for energy storage, including electric vehicles. Thus, testing processes must be able to meet the demands of the research needed for the technology to develop. Better testing equipment not only accelerates the testing process, allowing manufacturers to innovate and improve at a greater speed, but also makes testing and the creation of batteries safer overall.