The availability of fast-charging will be one of the biggest drivers for electric vehicle adoption. Current public direct current chargers can charge a vehicle up to 80% in half-an-hour to an hour — still quite a long time compared with the few minutes it takes to refuel an ICE vehicle. Multiple manufacturers and developers are now working to make fast-charging possible. Is technology finally ready to rapid charge electric vehicle batteries?

How fast is fast?

Depending on the battery as well as the charger, charging a typical 60kWh EV battery can range from 30 minutes to 8 hours. In urban areas where cars can be charged at home or in commercial car parks, this may not seem such a hassle, as cars can be charged while at work or overnight at home. However, in places where chargers may be few and far between, this number can be discouraging.

Across the industry, researchers and manufacturers are trying to bring down charging times to at least ten minutes, with some ambitious ones aiming for five-minutes; The latter rate would put charging EVs on par with refuelling traditional cars.

Why has fast charging been difficult to pin down?

Being electro-chemical cells, a battery’s stability is determined by multiple factors such as materials, temperature, usage, etc. If not taken care of well, a battery can deteriorate and become obsolete very quickly; fast-charging could accelerate this deterioration process.

A study from the University of California, Riverside conducted an experiment that found just this. After charging battery cells using the industry’s standard procedure for fast-charging EVs, they found that battery capacity reduced by as much as 40% after just 40 charge cycles. An EV battery is considered end-of-life below 80% capacity, so they found that cells were practically unusable after 25 cycles. After 60 cycles, the cells even split open.

Why is this the case? Fast-charging rapidly increases the internal resistance of a cell, which means that the usable capacity of a battery decreases. One reason for this is the build up of lithium plating, the process where lithium attaches itself to the anode and can be detrimental to the cell’s integrity. Moreover, when charging power increases, the heat inside increases as well. This leads to a build up of gas, causing the battery to swell, eventually leading to fire or explosion.

What is being done to make fast-charging possible?

Because of these reasons, changes have to be made on multiple fronts to make fast-charging viable. One method to accomplish this is by replacing certain materials within the cell.

In order to create their fast charging battery, Israeli company, StoreDot, focused on updating battery chemistry to support it. Most common lithium-ion batteries use a graphite anode. The company used germanium-based nano-particles which helped to address issues in safety, battery cycle life, and swelling. The battery design has been tested with consumer products, drones, and two-wheeled EVs. StoreDot has also manufactured cells to demonstrate the fast-charging capabilities on electric cars.

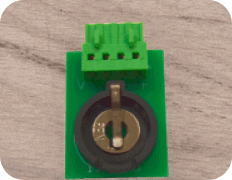

Another ongoing fast-charging project is from Penn State engineers who designed a lithium iron phosphate battery that can charge in just 10 minutes. The battery makes use of a self-heating approach to heat the battery up to 140 degrees fahrenheit in order to facilitate the charging process. Researchers also designed the battery with low-cost materials in order to make them mass market-friendly.

With continuous improvement in battery and charging technology, EV fast-charging may soon be widely available. While there still has to be other changes such as building infrastructure to support fast charging, this is step closer to decarbonizing transportation.

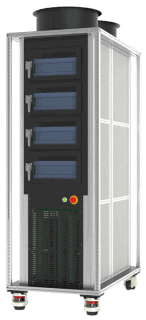

Find out more about how Arbin assists in the Electric Vehicle revolution here.