Introduction

No longer things of science fiction, flying cars are slowly becoming possible as many companies are working to release the first commercial and affordable flying car. These vehicles aim to be alternatives to conventional cars, and through their adoption alleviate road traffic, make short-distance travel faster, and provide a more environmentally friendly option for travel.

There are two design streams when it comes to flying cars currently under development. The first, eVTOLs (Electrical Vertical Take-Off & Landing), otherwise known as passenger drones, are close in concept to small drones seen on the market now. The second are hybrids, vehicles that have both wheels and wings and can operate on the road and in the air.

Plenty of companies have already developed prototypes. If the technology is already available, what is really stopping us from having flying cars now?

Why flying cars?

As the world taps into its finite fuel reserves, companies and researchers are racing to find efficient and affordable fuel and transportation alternatives. Electric vehicles (EVs) reduce the need for combustible fuel. They are also better for the environment as they reduce carbon emissions and noise pollution on the road. As a replacement for short-to-medium distance travelling, electrical flying cars would reduce the emissions from, and fuel used for trains, planes, and road vehicles.

Compared to electric cars, conventional cars are inefficient in their energy use. Currently, EVs convert around 60% of their energy to propulsion, while only 20% of every litre of fuel burned is used for forward motion in a conventional car. The rest is lost to heat and noise. In the same way, flying cars would allow for better use of energy when compared to fuel-based vehicles.

Commercial air travel has proven to be significantly safer than road travel. Thus, the standards set for the safety of flying vehicles would be higher than that of conventional cars, prompting developers to ensure they would be a safe option for daily use. Moreover, the advancement of technology has allowed for autonomous vehicles, aiming to eliminate human error. This technology is also being worked into flying cars.

Flying cars also allow for more mobility in a shorter amount of time. It would reduce the time spent commuting or stuck in traffic, giving people more time for other activities, like spending time with family and friends. In an urban city where life is busy and fast paced, the extra time would be warmly welcomed.

What still needs to be improved?

Technologically and economically, flying vehicles have not reached a level of efficiency which would allow it to be an effective mainstream option of travel. Ultimately, in order for electrical flying vehicles (eVTOL’s) to become reliable, safe, efficient, and affordable, battery technology still has a long way to go. Compared with jet fuel of the same weight, currently available batteries are just not as efficient for flying. According to one study, a single passenger eVTOL is still less energy efficient than electric road vehicles. The batteries of today are still unable to carry the amount of energy needed for flying vehicles to be considered energy efficient. Moreover, since these batteries would be extremely heavy-duty, the charge rate would be too slow to support flying vehicles as a high-frequency option for travel.

Besides capacity, the heat generated from the release of power is a huge concern. Batteries in eVTOLs and flying vehicles need to discharge much quicker than road vehicles, requiring special cooling systems, adding to the weight of vehicles. The extra heat would also shorten battery life and possibly make them more prone to catching fire. There are current problems with EVs catching fire while charging or after being involved in accidents. The instability of the safety of batteries must be addressed before flying vehicles can be considered a safe and viable option of public transportation.

What are the next steps?

Developing the right battery is still the key to creating a flying vehicle that can be clean, green, and efficient. Battery testing must also catch up with the needs of battery and vehicle developers to better understand what can be done to make them better. [Battery testing equipment] should be able to detect the smallest changes in the battery early in the testing phase so researches can quickly pick out factors that affect battery health. Equipment like Arbin’s cuts through the measurement noise present in lower quality equipment, allowing researchers to see minute changes and trends. Thus, more effectively assessing and predicting the efficiency and health of the battery.

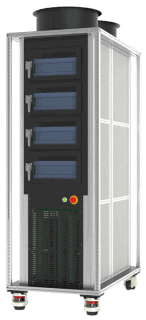

Temperature control equipment like [Arbin’s MZTC Multi-Chamber], also helps ensure superior measurement precision and safety during testing. Accelerating the [testing and development process] by reducing the chances of one battery cell affecting the other and causing issues like cascade failures. With flying car batteries, where heat and temperature control is crucial, having the right battery testing equipment is critical.

While solid concepts for flying cars are present and the projected benefits of using them are good, technology has yet to catch up to our imagination. However, once battery technology is able to meet the safety standards and efficiency needs of a flying vehicle, commercial, mainstream flying cars will become transportation of the present.