电动汽车电池测试

电动汽车(EV)电池的测试需要能够解决这些电池在道路上面临的独特使用条件的设备。Arbin与世界各地的电动车行业领导者合作,为动态驾驶循环模拟、与电池管理系统(BMS)的通信以及更多电动车电池解决方案提供全面的电池测试解决方案。

Arbin的先进技术

- 电动汽车电池测试的全面解决方案

- 具有数千个数据点的动态驱动曲线模拟

- 用于温度稳定的电池隔离测试室

- 与电池管理系统的CAN总线通信

客户评价

“We did side-by-side comparisons of Arbin and other tester technology. Armed with this data, we moved forward with confidence using Arbin for what is critical to our electrification [EV] future.”

- T. 米勒,福特汽车

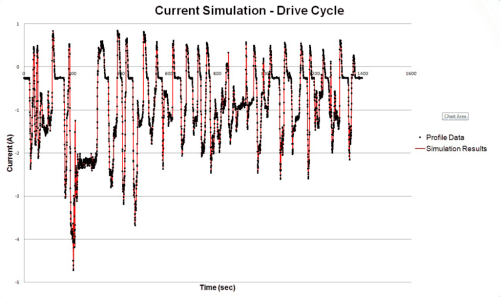

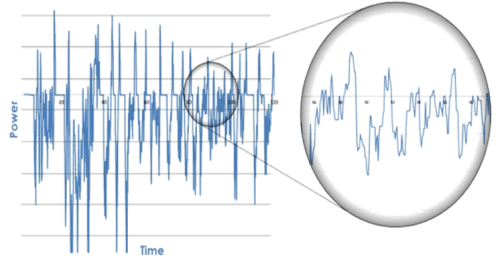

驱动曲线(驱动周期)的模拟

与传统的电池循环可能使用恒定电流和恒定电压(CC-CV)的充电/放电曲线相比,电动汽车测试应用要求电池和电池组根据动态驱动循环曲线进行充电/放电。Arbin通过简单地从xlsx、csv、txt等文件中加载时间-功率或时间-电流数据的文本文件,使执行这些驱动循环模拟不费吹灰之力,无需额外编程。驱动周期曲线可以有数百万个数据点,间隔时间快至10毫秒。

Arbin testers use a power embedded microcontroller for each channel module, so each test channel can perform a unique drive cycle simulation. Additionally, Arbin supports real-time drive profile simulations that can be controlled externally using CANBus protocols.

真正的双极电路

Arbin电池测试系统使用真正的双极电路,因此在充电和放电之间没有切换。在进行电动车电池测试的动态驱动周期模拟时,这一点至关重要,并允许Arbin测试仪精确复制和测量这些驱动曲线的影响。不使用真正的双极性电路的测试设备在用示波器测量时,会有不希望出现的spkes和电流输出下降,即使系统直接报告的数据可能不显示这种现象。

Arbin的工况模拟测试

电动汽车电池组的驱动曲线模拟

电动车测试和温度

Electric vehicle battery testing typically requires a temperature-controlled test environment. By default, US regulators state that all EV cell testing is performed at 30°C unless otherwise stipulated. Arbin has created an innovative temperature chamber for testing EV cells known as the “MZTC” Multi-Chamber.

This cell-isolating battery test chamber isolates each cell or pair of cells (depending on cell size and amperage) to create a safer test environment and maintain greater temperature stability. Each of the 8 mini-chambers offers a unique temperature setpoint and is thermally isolated from the others to prevent thermal run-away or cascading failure events. Arbin’s MZTC battery test chamber also makes connections and interfacing with cells easy.

Arbin还可以选择与其他制造商的各种第三方温度室连接。该软件与世界上大多数主要的试验室控制器模块兼容,因此Arbin试验箱可以在试验过程中自动调节温度。

Arbin电动汽车电池组测试仪,带测试室

Arbin MZTC电池测试室

与电池管理系统(BMS)的通信

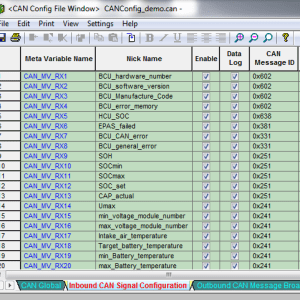

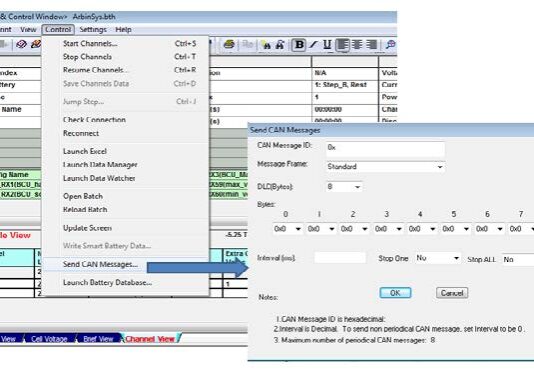

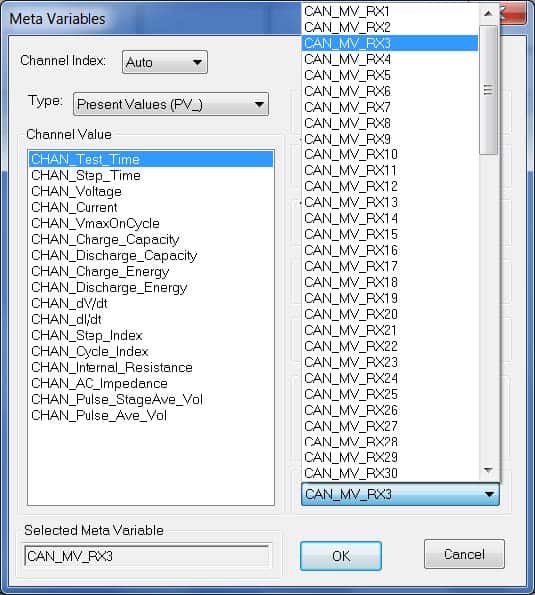

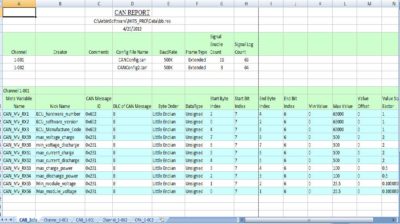

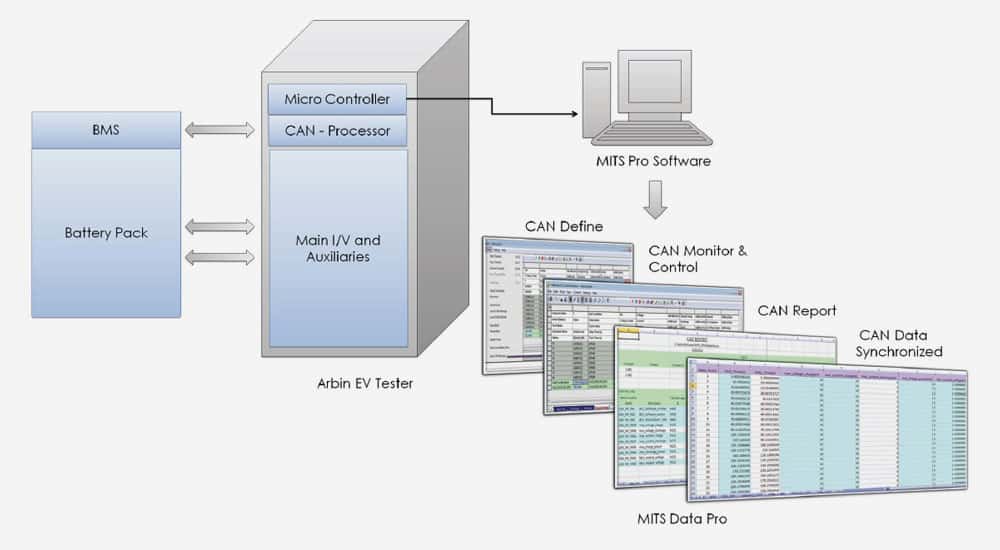

Arbin battery test systems offer an optional CAN Bus interface to communicate with the battery management system (BMS) of electric vehicle battery packs. Arbin’s interface allows both the sending and receiving of CAN messages between the tester and BMS. No third-party equipment, DLL packages, or licenses are needed. It is a complete CAN Bus solution that allows the user to enter or upload their CAN protocols, assign nicknames, and then control the test using these variables and record all data from the BMS to compare with Arbin’s own charge/discharge data.

Arbin测试器可以通过CAN总线进行实时控制,包括将CAN信息指定为动态控制值(即根据CAN信号进行动态充电)。这种实时控制可以来自BMS或其他外部来源,在测试期间BMS被建模的情况下。

电池管理系统通信

Arbin battery test systems offer an optional CANBus interface to communicate with the battery management system (BMS) of electric vehicle (EV) battery packs. Arbin’s interface allows both the sending and receiving of CAN messages between the tester and BMS. No 3rd party equipment, DLL packages, or licenses are needed.

It is a complete CANBus solution that allows the user to enter or upload their CAN protocols, assign nicknames, and then control the test using these variables and record all data from the BMS to compare with Arbin’s own charge/discharge data. The Arbin tester can be controlled via CANBus including assigning a CAN message as a dynamic control value. (i.e. charge dynamically based on a CAN signal.)

Arbin CAN接口

发送CAN信息

选择测试中使用的CAN变量

Arbin的CANBus数据内容报告

Arbin CAN接口

辅助底盘

用于动力电池组测试的辅助信号采集

测试电池组和模块可能需要监测单个电池的电压和/或温度。热电偶或热敏电阻可用于监测外部电池室的温度。辅助输入也可以测量更大的电池组内的电池,并允许将这些数据与BMS的数据进行比较(当使用CAN总线接口时)。

辅助输入是在一个小型的外部机箱中提供的,它与Arbin主系统联网,允许高度灵活的配置(内置以太网网络)。数字和模拟电压信号可用于与其他硬件一起发送/接收,如激活BMS的数字继电器信号,或通知测试准备就绪时进行。

Arbin’s Mits Pro Software

Arbin’s Mits Pro software provides the ability to control tests based on current, voltage, power, load, and c-rate, both with constant and dynamic control Built-in functions are available for Internal Resistance (IR) measurement, drive cycle simulations, mathematical functions, current and voltage ramps, looping, and much more There are over 90 pre-defined meta variables available to use and users may define and assign custom variables.

平行测试通道

有时需要并联测试通道的能力,以实现电动车电池测试所需的高c-rates。单独的Arbin测试通道可以被组合起来,使它们作为一个整体运作,以增加电流处理能力。这一操作在最新的Mits Pro软件中很容易执行。

用Arbin仪器测试电动车电池的安全性

Arbin systems have multiple layers and redundant safety features to help ensure a failsafe test environment. With Arbin’s testing solutions, you have precise control over safety limits for an entire test, specific steps in the test, and several AI-controlled safety monitoring limits designed by Arbin’s expert engineers. Arbin also uses an exclusive high-power distributed control network that manages a greater number of high-efficiency modules so they last longer and are easier to maintain.

Arbin在电动汽车电池测试方面的优势

At Arbin, we understand the vital role energy storage plays in our everyday life - and its importance to our future. This is why we work hard to provide the best service and testing equipment as a tool for both research and industry. Arbin’s state-of-the-art technology, powerful and flexible software, data capabilities, auxiliaries, and support are all part of the Arbin advantage. Learn more about the benefits of Arbin Instruments’ solutions.

Arbin的动力电池测试

Learn more about Arbin’s test equipment and features for EV battery testing and start creating your complete Arbin battery testing system today.