Overview

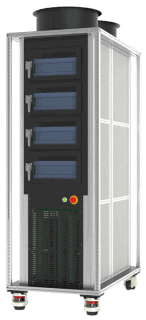

MITS 11

Unified Control

All-in-One App

Streamlined and User-Friendly Interface

MITS 11 now features a user-friendly design with a modern, web-like interface. The menu is organized to align with the steps of the testing process, providing a seamless and intuitive experience.

Users can now enjoy a smooth testing workflow by following the clearly structured menu. Additionally, we offer Built-in Schedules to save users time by automating repetitive tasks.

Features like Test Plan and Live Monitoring are also included to help users better organize and manage their tests.

Discover these features and more-explore MITS 11 today and experience the future of battery testing!

Cross-Platform Compatibility

Advanced Battery Testing Features

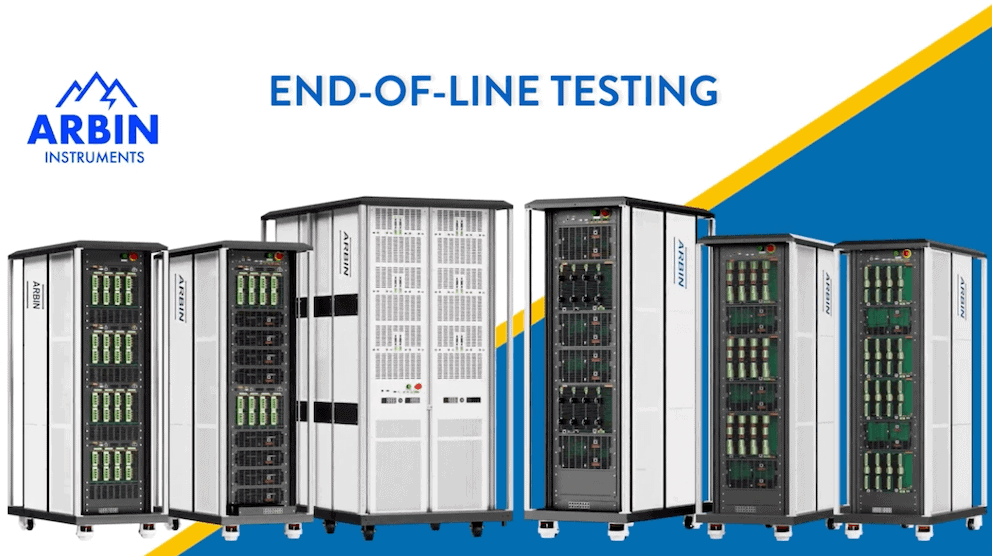

EOL (End of Line)

A quality assurance test system developed by Arbin, offering streamlined standard quality checks for your batteries.

DCIM (Battery Simulation Functions)

Utilizing Arbin's latest algorithms, this feature provides deep insights into the battery's internal structure, offering additional data to enhance your testing process.

.png)

These are just a few examples of what MITS 11 offers.

Explore more advanced features in MITS 11

Enhanced Data Solutions

We provide a variety of local and remote database options, including Microsoft SQL Server and PostgreSQL. To further ensure data security, MITS 11 supports cloud-based solutions such as Azure Cloud, Google Cloud, and AWS.

These databases serve as reliable backups, giving our customers peace of mind against data loss. For optimal data performance, MITS 11 integrates Kafka for processing and transferring data between hardware and software, leveraging the scalability and reliability of Apache Kafka on the cloud.

Seamless Integration via Robust API

DAS Multi-System Design Structure

Previous Arbin System Solution

In our previous MITS system, we employed Windaq as the desktop controller, paired with an Arbin system. Typically, this setup involved a primary IV system, which might be connected to several auxiliary machines.

However, this architecture was inherently limited: each controller center (PC) could only communicate with and control a single Arbin system at any given time. This restriction was due to our system's reliance on recognizing each machine through a singular IP address.

While we explored solutions that allowed for multiple machine connections via an internet switch, these approaches were still burdened with significant limitations, including complexity, latency, and reduced flexibility. This led us to re-engineer our controller system to overcome these constraints and enable more sophisticated, multi-system control capabilities.

Our solution is the development of a new generation of Windaq software, which we have named DAS (Distributed Application Service). The key innovation in DAS is the creation of an additional software layer that manages parallel tasks. This layer facilitates the simultaneous control of multiple Arbin systems by leveraging individual interfaces that are isolated across different subnets (e.g., 196.168.1.x, 196.168.2.x).

New DAS Solution

Key Benefits of the New DAS Architecture

Multi-System Control

With the new structure, we can control multiple Arbin devices through a single controller-whether it's a PC or a DAS server-without the need for additional hardware like internet switches. This streamlined approach reduces complexity and potential points of failure in the system.

Simultaneous Command Execution

The DAS architecture allows for simultaneous command execution within a 100ms window. This rapid response time is crucial for high-stakes testing environments, where delays can compromise data integrity or test outcomes.

Cross-System Communication

One of the most significant advancements in DAS is its ability to facilitate cross-system communication for synchronized control. This means that different Arbin systems can now communicate and coordinate with each other in real-time, enabling more complex testing scenarios that were previously unattainable.

Enhanced Scenario Handling

The new DAS structure excels in managing complex, multi-system testing scenarios. For instance, it can now seamlessly control auxiliary machines across different IV systems.

An example of this would be one IV channel focusing on capturing data output from a connected auxiliary machine, while another IV channel responds dynamically to that data with a large current output. This cross-system responsive control is a significant step forward in testing efficiency and precision.

Centralized Monitoring

Although our previous system allowed for centralized monitoring to observe the status of different systems, DAS takes this a step further by enabling active, synchronized control across these systems.

This ensures that all systems are not just monitored but are actively working together to achieve the desired testing outcomes.

Previous centralized monitoring solution