Innovation

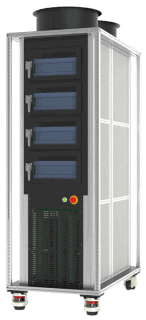

As a leader in battery testing, manufacturing, and research, we drive innovation that sets industry standards. For over 30 years, our advanced technologies have transformed battery research and testing, empowering researchers and manufacturers to achieve superior performance and shape the future of energy storage.

Cutting-edge technology and an innovative alternative to the traditional ACIM technique for measuring battery impedance, uses Galvanostatic and AI Prediction Modeling Methods provide distinct advantages without additional equipment is required, shorter test times, and it maintains accuracy comparable to ACIM.

SDCM is essential for evaluating a battery's state of health, predicting its performance, and estimating its lifespan. We have revolutionized this method, making it significantly faster and more accurate while lowering equipment requirements.

Arbin applies this structure into several applications