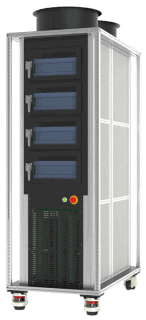

Regenerative Battery Test Series

RBT Product Range

| Channel Voltage | 60 - 1,500V |

| Channel Current | 50 - 1,000A |

| Regenerative Efficiency | >90% |

Arbin’s Regenerative Battery Testing (RBT) series is specifically designed for testing high-power battery packs. Engineered with electric vehicles, military technology, and stationary grid storage in mind, these pack testing systems can simulate complex, real-world applications such as drive profiles, cranking amp applications, and other custom profiles. The regenerative circuitry within each RBT system allows power to be discharged back to the grid, making it a more economical battery test solution for pack voltage up to 1000V and maximum power up to 1MW.

Arbin's RBT Series Standard Models

Small module and pack testing up to 200V

- Voltage from 60V up to 200V

- Current ranges from 100A up to 600A

Voltage Range: 5V to 60V (0V Option)

Channel Max Current: 100A up to 600A

Channel Count: 2~18+

Mid-size modules and packs up to 600V

- Voltage from 400V up to 600V

- Current ranges from 100A up to 500A

Voltage Range: 15V to 400V

Channel Max Current: 100A up to 500A

Channel Count: 2~12+

High voltage pack testing up to 1,500V

- Voltage from 700V up to 1,000V

- Current ranges from 100A up to 300A

Voltage Range: 18V to 700V

Channel Max Current: 100A up to 300A

Channel Count: 2~12

Reliable Performance with Arbin's Regenerative Battery Testers

±0.05% FS Control & Measurement Accuracy

16-Bit Control & Measurement Resolution

All Arbin regenerative test systems have 16-bit control and measurement resolution, and ±0.05% FSR accuracy to provide the highest quality results in the industry.

True Bipolar Power Supply

Arbin’s true bipolar power supply has no switching time between charge/discharge, so dynamic EV drive profiles are accurately performed. Leading competitors have 5ms+ switching time which causes drive profiles to lag over time.

Power Factor >0.99

Regenerative Circuitry with >90% Efficiency

100% Duty Cycle

Highly efficient circuitry and power density minimize the cost of operation compared to similar systems. Each Arbin RBT system is engineered and over-built to handle 100% duty cycle at maximum power.

Data Sampling at 0.3ms

Data Logging at 5ms or 2000 pts Per Second

High performance integrated microcontrollers allow fast data sampling, and ability to log every detail of the charge/discharge simulation.

Each RBT system comes standard with multiple current ranges, and each current range can be tailored to fit your application.

Current rise time is also excellent, specified at 10ms or less (depending on your system’s current specification).

All channels are fully independent, but can also be combined to operate in parallel for increased current-handling capacity.

Regenerative Battery Test Equipment for Advanced Simulations

Arbin's RBT series of battery test equipment is capable of advanced, high-speed simulations. Users can upload pre-defined data or control the simulation dynamically via CAN communication.

Key Features:

- Profile Types: Time vs. Current, Time vs. Power, Time vs. Load

- Up to 1 million data points

- True Bipolar Circuitry so no switching between charge and discharge

- Data Acquisition Range: Up to 5ms

Compared to traditional battery cycling that may use exclusively constant current and constant voltage (CC-CV) charge/discharge profiles, EV testing applications require charge/discharge based on various real-world applications. These charge/discharge profiles are highly dynamic and require much greater current demands relative to “traditional” testing.

CANBus Communication and Regenerative Battery Testing

Arbin's RBT is the only tester that allows dynamic control of charge and discharge via the CAN protocol. This functionality allows users to control the Arbin tester with a Battery Management System (BMS).

CANBus Features of the RBT Series:

- Allows BMS to fully control RBT charge/discharge

- Easily import CAN database and customize

- Read/write integration with battery management system

- Offers easy-to-navigate drop-down menu selections

- Create customized CAN reports to compare BMS data

- No 3rd-party equipment, DLL package, or license is needed

- Extended or Standard Frame Type

Reliable and Safe Battery Pack Test Equipment

Battery pack testing requires both dependability and safety, two core design principles in Arbin’s RBT series. To provide a safe, high-performance solution for high-power testing, the latest RBT systems feature improved thermal management, redundant microcontrollers to ensure failsafe testing, and built-in UPS to ensure a proper shutdown sequence in case of input power failure. These features for battery pack testing are in addition to the safety features that are standard to Arbin battery test equipment.

Auxilaries and Optional Accessories Available to Enhance Testing

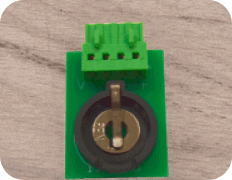

CANBus

Arbin offers CANBus interface(s) to allow real-time external control of the Arbin tester using CAN protocol. This feature allows for battery module/pack communication with a BMS (battery management system) or for cell testing where the client needs external control via CAN.

MTCI

The Temperature Chamber Interface (MTCI) allows the Arbin system to communicate with an approved third-party temperature/environment chamber. Arbin’s software can turn the chamber on/off and adjust the temperature during the test.

Control Power Supply

The Control Power Supply (CPS) provides multiple inputs that allow the Arbin test station to fully integrate with the facility, and allows the system to receive signals, display status with a safety tower light, and can be remotely shut down by the user.

Arbin offers thermocouple and thermistor sensor types to measure and record temperature during testing. They function independently so the user may flexibly assign them in any configuration with the main charge/discharge test channels. All data is automatically synchronized with the cell charge/discharge test data. Available sensor types include:

- K-Type Thermocouples

- T-Type Thermocouples

- PT100 Thermistor (NOTE: PT100 thermistor inputs are compatible with Arbin MZTC Multi-Chamber.)

- 10kOhm Thermistor

Contact Us Today for a Quote

Complete our contact form to request a quote or learn how battery test equipment from Arbin Instruments can meet your testing requirements.