Batteries commonly have two electrodes: anode and cathode. Ions travel through the separator to either electrode during the charge and discharge cycles and release energy in the process.

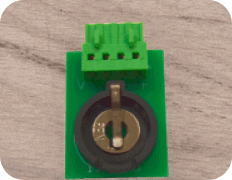

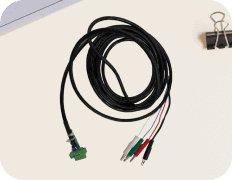

Battery test cells can be built to include a third electrode. This is known as the reference electrode (RE). The RE allows for greater analysis of battery performance as it decouples test results between anode and cathode.

When researching battery materials, the use of a reference electrode (RE) allows researchers to measure and differentiate the contribution of each component of the cell to its overall performance. Three-electrode experiments help identify which electrode (anode or cathode) limits the cell performance during long-term testing. It is important to identify how each electrode is contributing to cell degradation under various test conditions instead of blindly experimenting with one or both.

Why is this important?

Most all electrochemical experiments and battery tests provide greater understanding of the cell when the anode and cathode results can be decoupled through use of a reference electrode. This extends to what are traditionally considered “industrial” applications as well. The dynamic charge-discharge profiles and fast charge simulations associated with commercial devices and electric vehicles can draw unique performance from a battery compared to low-rate constant current cycling.

Three-electrode testing is also beneficial for evaluating battery safety. Minter and Juarez-Robles highlight how fast-charging, which is a highly sought characteristic for electric vehicles, creates a great need to detect and monitor lithium plating occurring on a cell anode. [Minter RD, Juarez-Robles D, et al 2018 J Vis Exp., (135):57735.] This can best be achieved using a three-electrode cell during testing.

One fundamental goal of battery research is to develop cells that are long-lasting. This is especially important for electric vehicle and grid storage applications where the commercial cells and battery packs must last thousands of cycles and up to 10 years. Three-electrode testing allows researchers to identify the limiting factor in their cell to focus attention where improvement is needed most.

How the reference electrode is used in different testing situations

-

During HPPC test, which are common for electric vehicle applications, the use of a reference electrode reveals electrode polarization.

-

Performing EIS shows the decoupled impedance from anode and cathode individually when a three-electrode cell is utilized.

-

The individual contribution of anode and cathode is revealed when demonstrating lithium loss due to SEI growth as a dominant aging mechanism.

-

Differential capacity analysis can reveal changes in the voltage profile of anode and cathode and how they individually contribute to cell degradation.

The obstacles in creating a stable and reliable three-electrode cell

Comparing results from a new three-electrode experiment to other published results needs to keep as many variables consistent as possible, such as electrode size, material amount, cell uniformity, etc., or else attempt to normalize results. This is a principal reason why traditional cell types are modified to incorporate a reference electrode as “homemade” cell, so results are easier to compare with minimal normalization. Researchers wish to demonstrate and compare their results to existing two-electrode data of the same cell type (cylindrical, pouch, coin). However, since most battery material work is conducted using coincells, this is the natural choice for three-electrode experiments to compare the new results with the vast amount of tradition two-electrode data in publication. The new experimental data will decouple the anode and cathode and provide new insights.

Suggestion

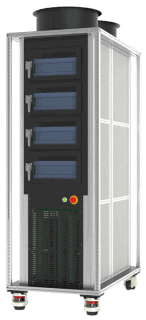

A wide range of three-electrode cell configurations—such as Swagelok-style cells, split-cell designs, and PAT cells—are available and commonly used for electrochemical studies. However, it is important to recognize that these systems also have limitations. They can be expensive, complex to assemble, and challenging to scale for practical applications. Additionally, data obtained from such specialized cells must be carefully normalized when compared with conventional battery formats (e.g., coin, cylindrical, or pouch cells). Therefore, these considerations should be thoroughly evaluated when selecting an appropriate testing configuration for your specific research or development objectives.