Auxiliary

To complement our main battery test equipment systems, Arbin Instruments also offers a full complement of auxiliary modules to address further testing requirements. These modules expand testing capability beyond the main charge/discharge control circuitry and can be placed in either the main chassis or a small external chassis, making it easy to add auxiliary options to your existing systems.

Measurement Auxiliaries

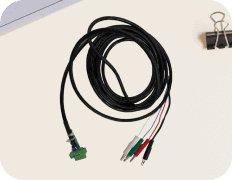

Auxiliary Voltage Inputs

Secondary voltage sense leads can be added to any Arbin system to provide additional reference electrodes in a multi-electrode experiment or to monitor cell voltages within a pack.

- 8 inputs per module

- 0.02% accuracy

- Up to 100G Ohm input impedance

- (-5) to 5V

- (-10) to 10V

- (-25) to 25V

- (-50) to 50V

- (-100) to 100V

Auxiliary Temperature Inputs

Temperature can be used as a safety limit and to control the test. Inputs are provided for each of the sensor types listed.

- 16 inputs per module

- 0.2~1°C accuracy

- Type-T Thermocouple

- Type-K Thermocouple

- PT-100 Thermistor

- 10k Ohm Thermistor

Auxiliary Pressure Inputs

The Pressure Input option can be used to record pressure measurements with pressure transducers and works similarly to the 2nd voltage measurement.

- 16 Channels

- 0 ~ 100mV or 0 ~ 10mV Pressure Sensor Output Voltage Range

- ±0.1% FSR Measurement Accuracy

- 100G Ohm Input Impedance

- 15V Output Supply to Sensor

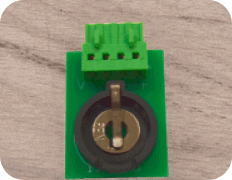

Electrochemical Impedance Spectroscopy (EIS) Interface

Arbin's EIS Integration solutions are designed to support full or half-cell battery characterization or any other electrochemical device. Arbin's EIS board can easily integrate with your cycler for lower frequency needs. Arbin also has an integrated EIS solution that combines the multi-channel, high-precision battery test performance of Arbin with advanced EIS capability for higher frequency. These solutions share up to 64 Arbin channels (through multiplexing) with a single EIS unit to maximize the duty cycle of both instruments. No change in connection is necessary.

- Frequency Range of 10μHz to 100kHz Integrated With Arbin Cycler

- Available on Arbin LBT, LBTS, and HPT Systems

- Gamry 1010E

- Gamry 5000E

- Gamry 5000P

- Gamry Ref 3000

External Control Auxiliaries

Multiple Temperature Chamber Interface (MTCI)

The TCI module allows the Arbin system to communicate with an approved third-party temperature chamber. Arbin's software can turn the chamber on/off and adjust the temperature during the test. Note: Arbin also offers a compact Multi-Chamber below for cell-testing applications.

- 1 module controls 1 chamber

- 13" x 7" x 3" Chassis Dimensions

- Request list of compatible controllers

- RS232 Compliance Standard

CAN Bus

The CAN Bus options allow the Arbin system to communicate with the battery management system inside a battery pack. The Arbin system can also be controlled by external CAN messages such as from a BMS or external modeling software.

- Available per channel

- CAN 2.0, CAN FD Protocol

- 13" x 7" x 3" Chassis Dimensions

Analog Output and Digital Input/Output (AO, DI/O)

Analog and Digital Input/Output channels allow the Arbin system to interact with external hardware and devices through a digital on/off relay signal or an analog 0-10V signal. Typical uses include pumps, flow meters, valves, etc., for flow battery applications.

- 8 Analog Output per module

- 16 Digital I/O per module

- (-10) ~ 10V Analog

- Digital Relay

Options

Auto-Calibration

The Auto-Calibration module enables the Arbin system to self-calibrate automatically.

- 1 module applies to all channels

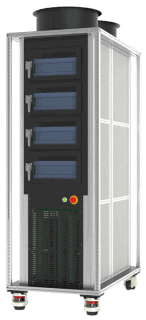

Arbin Multi-Zone Temperature Chamber (MZTC)

The MZTC Multi-Chamber provides 4 or 8 fully independent mini-chambers with a temperature range of [ambient-10] to 60°C. Each mini-chamber can hold 1 to 4 cells depending on cell type and amperage. Racks are available for multiple MZTC units.

Battery Holders and Racks

Battery holders and racks, available in a variety of configurations, provide convenient storage and access for batteries under test, as well as contributing to a safer testing environment.