Revolutionize Your Battery Formation Process

Experience unparalleled performance and reliability in battery formation with our cutting-edge, patented technology. Designed for a faster, safer formation process, Arbin battery formation solution enhances operational safety while significantly lowering maintenance requirements and capital expenditures. Streamline your entire operation for maximum efficiency and peace of mind.

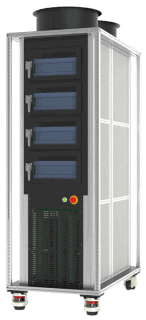

Arbin SPT Cell Formation Solution

336 channels for 18650/21700 cell or 128 channels for 46xx cell, custom design available for prismatic and pouch cell.

Patented(US11933860B2) Series Parallel Technology(SPT) structure

Covers complete battery formation process

Equipped with Self-Discharge Current Measurement(SDCM) feature

Monitoring each cell's self discharge current by conducting SDM step at different formation stage, thus detects cell failure at early stage, hours/days before cell's thermal runaway.

No need for temperature measurement per cell

No need for smoke alarm per cell

No need for off gas sensor

Faster formation process(reduce OCV measurement time)

Lower expenditure for environment/building/safety measure and material movement

>50% saving of formation time with better QC

SPT Formation System

Large Scale Cell Formation

- Turn-key solution for large-scale formation and grading

- Reduce facility space requirements by up to 50%

- Lower equipment, operation, and maintenance costs

- Individually, pilot system comes with PC and control software; scales to factory level using webAPI, MQTT, and OPC-UA

Manufacturing Line Solutions

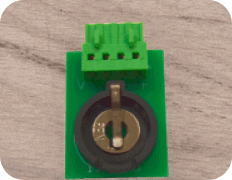

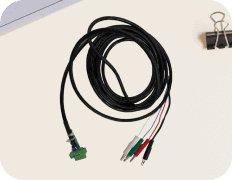

Engagement System Design

Versatile Design with Adaptable Battery Tray paired with universal engagement system. Seamless Robot Integration allows robot to effortlessly pull and insert battery trays. Designed to be compact while incorporating comprehensive safety mechanisms for reliable operation.

Series Parallel Cell Formation Structure

Arrange cells with parallel and series connection during formation process. Each cell's current and voltage are monitored individually in real time. Formation current distributed among paralleled cells naturally based on their real capacity. Higher overal voltage allows for higher regenerative efficiency during discharge. Early-stage detection of cell failure hours/days before cell thermal runaway

Cell Finishing Process Comparison

Traditional Formation Procedure

Arbin Formation Procedure

Patented Series Parallel Technology (SPT) structure covers complete battery formation process, reduce 30%~50% of formation time by replacing traditional OCV measurement with Arbin Self-Discharge Current measurement.

Arbin Automation and Material Movements

Arbin main testing channel are shared with multiple distributed battery engagement trays for sequential formation, then each distributed battery tray covers all other procedures(aging, SDM, grading, IR...) by themselves. Greatly reduce the equipment capital expense and operation expense for the same throughput.

Early-stage Battery Failure Detection

Arbin SDCM feature detects cell failure at early stage, hours/days before cell's thermal runaway, thus reduce the need for temperature measurement, smoke alarm or off gas sensor for each cell.