Articles

Driving Battery Innovation: Arbin at The Battery Show India 2025

We are excited to share that Arbin will be participating in The Battery Show India 2025, taking place from October 30 to November 1 at the India Expo Mart & Centre in Greater Noida. As a global leader in high-precision battery testing technology, Arbin provides advanced solutions for battery cells, […]

How to run cyclic voltammetry on three-electrode(3E) cell using Arbin Tester

I. Introduction to 3E cell In a battery with 2 electrode, when you measure the battery voltage, you measure the potential difference between the cathode and anode of the battery. In this case, you only see the total difference in potentials and do not know how much each electrode contribute […]

Arbin at The Battery Show North America 2025 — Empowering the Future of Energy Innovation

Arbin Instruments was honored to participate in The Battery Show North America 2025 in Detroit — the largest gathering of professionals driving innovation in advanced battery and electric vehicle technology. The event brought together global leaders, researchers, and manufacturers to discuss emerging trends, sustainability, and the technologies shaping the future […]

Moments of Collaboration: Arbin’s Successful Engagement at ICNaB 2025

The event photos from ICNaB 2025 clearly showcase Arbin’s strong presence and successful customer engagement. You can see our team interacting with attendees, demonstrating technology, and explaining solutions to interested visitors. The images capture genuine exchanges — customers asking questions, sharing ideas, and engaging with Arbin staff. Overall, the photos […]

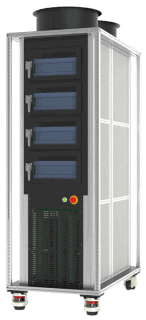

Overview about what Arbin products to choose-1

Arbin’s Battery Testing Systems Arbin’s main products are advanced battery testing systems that accurately simulate real-world charge and discharge cycles. These systems help researchers, engineers, and manufacturers evaluate battery performance, safety, and lifespan under a wide range of conditions. Key Specifications Two of the most important specifications of a testing […]

Arbin to Exhibit and Present at Batteries Event Lyon 2025 — Join Us in November

We’re excited to share that Arbin Instruments will be attending Batteries Event 2025 in Lyon, France from November 4 to 6, 2025. Batteries Event is one of Europe’s premier gatherings for the full battery value chain — from raw materials and cell design to manufacturing, testing, second-life, and recycling. Batteries […]

10th International Conference on Sodium Batteries (ICNaB) 2025 in Sydney

We are excited to announce our participation as a sponsor at the 10th International Conference on Sodium Batteries (ICNaB) 2025, hosted by the University of Technology Sydney. The event location is Amora Hotel Jamison Sydney, 11 Jamison Street, Sydney, NSW 22000. This prestigious event serves as a vital platform for leading […]

How to run cyclic voltammetry(CV) using Arbin Tester

Arbin continues to power innovation in many areas of battery research, including electrochemical experiments such as cyclic voltammetry (CV). Arbin equipment is designed to perform electrochemical experiments with the precise circuitry required for linear voltage ramps, while the MITS software gives the user a wide variety of options to create […]

How to perform DC Internal Resistance measurement with Arbin?

Mechanism explanations: Arbin’s MITS software uses pulse method to calculate IR. In order to achieve better accuracy, the software measures the IR 10 times and takes the average. The pulse looks like the graph bellow: IIR is the amplitude value T2 is the extra control value1 I0 is the offset […]

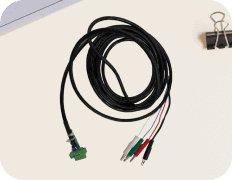

Enhancing Battery Testing Safety with a Door Switch Interlock System

I. Purpose and Applicability Battery testing—whether for electric vehicles, consumer electronics, or industrial systems—demands strict safety protocols. One often overlooked but critical element in test chamber safety is the door switch interlock system. This simple yet powerful mechanism helps prevent injuries, equipment damage, and test data corruption. In this article, […]

Integration of Arbin Instruments with Gamry Potentiostats for High-Frequency EIS up to 2 MHz

According to the standard specifications published by Arbin, integrating a Gamry device with an Arbin system typically limits the device’s original frequency capability from 2 MHz down to 100 kHz. However, in this article, we will introduce a solution that allows the system to retain the full 2 MHz frequency, with some trade-offs […]

How to perform Internal Resistance measurement according to IEC 61960 with Arbin?

IR measurement is crucial to have an insight into a battery. There are many way, i.e. many standard to measure battery’s IR. This article will introduce IEC 61960 standard and how to implement it using Arbin’s equipments. IEC 61960 standard for battery IR: In this standard, a discharge pulse of […]

Integrated Electrochemical Impedance Spectroscopy (EIS) With Arbin Charge/Discharge Channels

Introduction Electrochemical Impedance Spectroscopy (EIS) is a foundational diagnostic technique for evaluating battery health, internal resistance, degradation mechanisms, and electrochemical behavior over time. However, EIS is traditionally limited by hardware complexity and high per-channel cost, making it difficult to scale across large battery test systems. To address these challenges, Arbin […]

How to Test a Protection Circuit Module (PCM) Using ARBIN EOL

I. Purpose and Scope: The Protection Circuit Module (PCM) is a critical electronic component responsible for monitoring and protecting devices across a wide range of applications—from small consumer electronics to large-scale industrial equipment. Its core function is to ensure battery and device safety by preventing hazardous conditions such as overcharging, […]

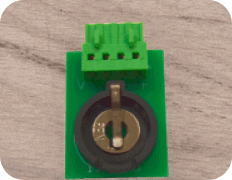

Auxiliary Voltage Measurement

Introduction The Arbin Auxiliary Voltage Input Module enables precise, high-resolution voltage monitoring for battery testing applications that require measurements beyond the standard I/V channels. Typical use cases include monitoring individual cell or module voltages within a larger pack, measuring reference electrodes in three-electrode cells, or comparing BMS data with directly […]

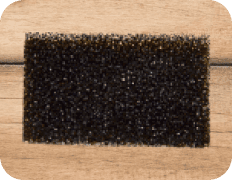

Auxiliary Temperature Measurement

Introduction Battery temperature measurement is essential for evaluating safety, longevity, and performance in modern testing environments. Arbin supports three primary sensor technologies—thermocouples (Type T and K), RTDs (PT100), and thermistors (10kΩ)—each available through dedicated auxiliary input modules. These sensors enable precise temperature control, monitoring, and safety logic throughout battery R&D […]

Constant-C-rate w.r.t. actual capacity, rather than constant current with Arbin cyclers

As we all know, the batteries’ capacity degrade by cycle of charge and discharge. If we set the charge and discharge current of a fixed value, such as 1A, 2A,… the length of each cycle will gradually decreases, simply because the battery’s capacity decreases: Cycle time = (Charge Capacity + […]

Synchronize different battery charge/discharge channels in one environmental temperature chamber

MTCI Introduction Arbin’s MTCI (Multi-Temperature Chamber Interface) module offers seamless and sophisticated integration with third-party environmental chambers, enabling direct control of temperature and humidity setpoints from within the Arbin test schedule. This streamlined setup allows test engineers to program and adjust environmental conditions alongside electrical cycling parameters, eliminating the need […]

Formula and variables used in Arbin MITS software for flexible battery testing

General Description: – Software allows the user to control a test using variables rather than concrete control values (for example, instead of using 4.2V for control, the system can use “Last Step Maximum Voltage” as the control type for the following step. – It is also possible to use these […]

Battery multiple points temperature measurement

Importance of Temperature Monitoring in Battery Testing Accurate temperature monitoring is a critical aspect of battery testing to ensure both safety and data integrity. One key application is the prevention of thermal runaway or overheating during test procedures. When a battery exceeds a predefined temperature threshold, the test must be […]